History

-

2023

We launch our new employer brand #YourVoiceMatters.

-

2022

We have been awarded the contract to supply the new sewage sludge treatment plant in the Belgian region of Flanders.

Credit: FOSTER©

-

2021

We receive the order to supply grate and boiler technology for the new waste-to-energy plant in the Polish capital Warsaw. We are thus further expanding our market leadership in Poland.

WtE plant, Warsaw, Poland

Credit: MPO Sp. z o.o. w m.st. Warszawie -

We also win the contract to supply the new waste-to-energy plant in Wiesbaden. We are responsible for the planning, delivery, installation and commissioning of the new facility in the Hessian capital.

WtE plant, Wiesbaden, Germany

-

2020

We win the second contract for the delivery of a thermal waste treatment plant in the Polish market – Olsztyn – and thus secure market leadership in the country.

-

2018

Not only do we celebrate our 90th anniversary, but we also announce our re-entry into the market for thermal treatment of municipal sewage sludge. We also receive an order at the end of the year to supply CFB technology for the first fully biomass-fired power plant in Japan (Sodegaura).

-

2016

With high-ranking experts from the field of circulating fluidised bed we celebrate the 40th anniversary of the application for the most important CFB combustion patents for power plant applications of our company predecessor in 1976. The aim of the event was to shed light on the successful history of CFB over the past decades and at the same time discuss the future technological challenges against the background of the energy transition.

Impression of the CFB patent event at our premises

-

2012

We win the contract to supply technology for the thermal waste treatment plant in Krakow, Poland.

-

2011

The Doosan Group takes over the company – change of name to Doosan Lentjes GmbH.

-

2009

We are supplying the largest single process line in our history for the thermal waste treatment plant in Harlingen, the Netherlands. This thermally treats 280,000 tonnes of municipal and other pre-treated waste per year for the Dutch province of Friesland.

-

2007

Lentjes GmbH is taken over by AE&E (Austrian Energy&Environment) and henceforth trades under the name AE&E Lentjes GmbH.

-

2005

Lurgi Lentjes AG is renamed Lentjes GmbH.

We also conclude licence agreements for hazardous waste incineration based on rotary kiln technology with the Chinese company Zhongtian Environmental Protection Group. Based on this agreement, several plants are built in China, e.g. in Nantong, Chongqing, Shaanxi, Qinghai and Henan.

-

2003

Largest WtE order in our history: As general contractor, we are supplying four new incineration lines for the Frankfurt waste-to-energy plant. This included both the demolition of the existing plant and the refurbishment of the adjacent thermal power plant.

-

2002

First installation of a water-cooled reciprocating grate at the Colleferro thermal waste treatment plant, Italy.

-

2001

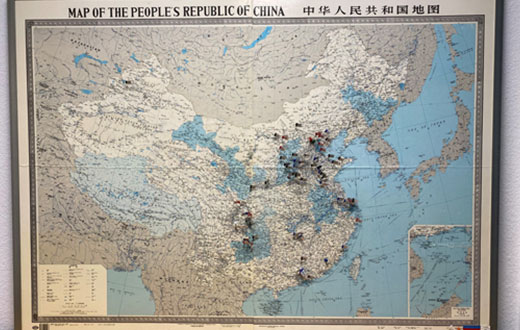

We conclude a licensing agreement for our wet flue gas desulphurisation with the Chinese company Shanghai Longking Environmental Protection Co.,Ltd. Further licensing agreements follow with other local companies – not only for wet flue gas desulphurisation, but also for CFB flue gas desulphurisation and the DeNOx technology SCR (Selective Catalytic Reduction). In total, 163 units will be built in China with our flue gas cleaning system on the basis of the various licences.

Map with flags at those locations where plants with Doosan-Lentjes flue gas cleaning technology have been built in China

-

2000

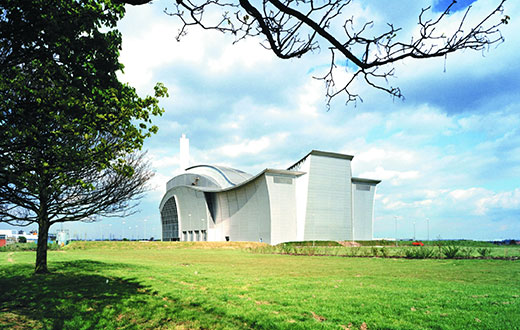

We are awarded the contract for the turnkey design and supply of two biomass-fired circulating fluidised bed (CFB) boilers for the Strongoli power plant in Italy. The project was subsidised by the Italian government in order to meet the Kyoto Protocol’s climate change mitigation targets.

In addition, the first contract for the refurbishment of the Shimonoseki waste-to-energy plant in Honshu, Japan is awarded based on our licensing agreement with Kobelco Ecosolutions.

CFB power plant, Strongoli, Italy

-

1999

The new mono sewage sludge incineration plant in Belfast, Northern Ireland, which we supplied, goes into operation. Today, the plant is owned by Northern Ireland Water and operated by Veolia Water. For more than 20 years, the sewage sludge of the inhabitants of Belfast and the surrounding area has been thermally treated there very reliably.

-

1998

Near London, the two sister plants Beckton and Crossness are coming on stream, burning sewage sludge in mono operation in two fluidised bed boilers. Together, the plants we designed, built and commissioned treat the sewage sludge of about four million inhabitants over an area of about 550 km2.

-

1997

The first contract for the construction of a waste incineration plant in Kunpo, Korea, is awarded on the basis of our licence agreement with Hyundai Engineering & Construction.

-

1995

The new power plant in Gardanne, France, goes into operation as the world’s largest CFB plant. In 2013, we receive the order to comprehensively upgrade the plant and convert it to biomass. By 2034, the plant will have a capacity of 150 MW with a base production of more than 7500 hours per year, which is equivalent to the annual electricity consumption (except for heating purposes) of 440 000 households. This investment reduces the carbon footprint by 600,000 tonnes per year.

-

1994

Further development of sewage sludge incineration technology using the fluidised bed process.

-

1992

The fluidised bed activities of Lurgi AG, Lentjes GmbH and Deutsche Babcock Energietechnik GmbH merge to form LLB Lurgi Lentjes Babcock Energietechnik GmbH. The boiler and flue gas desulphurisation business and other technologies are merged to form Lurgi Lentjes AG.

-

1990

Lentjes GmbH is taken over by the former Metallgesellschaft.

-

1988/89

We enter the market for thermal waste treatment based on grate technology and install the first roller grate in the thermal waste treatment plant in Wuppertal, Germany.

-

1986

When West Berlin was still an island in the former Eastern Bloc, we received an order to supply a circulating fluidised bed combustion system (CFB) for combined heat and power (CHP) in the city of Berlin. This plant was the first CFB in the world to use the Benson process and cooled cyclones. In 1990, the plant received the International Power Plant Award for its high efficiency and low emissions. Thanks to the flexible CFB technology, the power plant has since been converted to co-firing biomass and continues to reliably supply the residents of Berlin with electricity and heat.

-

1985

We acquire Standardkessel GmbH.

-

1984

We acquire Gottfried Bischoff GmbH, a specialist in flue gas desulphurisation technology, and thus enter the market for flue gas cleaning in power plants and waste-to-energy facilities.

-

1982

We plan, build and commission the world’s first commercial CFB boiler in Lünen (circulating fluidised bed). The plant in Lünen is still in operation today as part of the recycling activities of the Remondis Lippe plant and burns a wide range of different waste fuels, proving the flexibility of CFB technology in terms of fuel use and emissions compliance.

-

1980

Carrying out a study entitled “Measures to reduce corrosion on the combustion chamber side” (original in German) at the Düsseldorf waste incineration plant – together with Stadtwerke Düsseldorf AG and Vereinigte Kesselwerke AG. The study was funded by the Federal Ministry of Research and Technology.

In addition, further development of the pulse-jet filter for cleaning flue gases from power plants and waste-to-energy facilities took place. -

1955

In 1955, the Ferdinand Lentjes Foundation was founded, which cared for people with disabilities and was active in animal welfare. The foundation later provided significant support for the construction of the Ferdinand Lentjes House in Düsseldorf, which provided 50 flats for severely disabled people and their families. The house still exists today and focuses on the nursing care and support of people with disabilities.

-

1927/28

The engineer and entrepreneur Ferdinand Lentjes founded Rheinische Rohrleitungsbau GmbH in 1927 and Ferdinand Lentjes Kesselschmiede und Maschinenbau the following year, which was based in Düsseldorf.